invisible

- MAJOR APPLIANCES

-

SMALL APPLIANCES

- BREAKFAST

- Kettles

-

Toasters

- Citrus juicers

- separator1

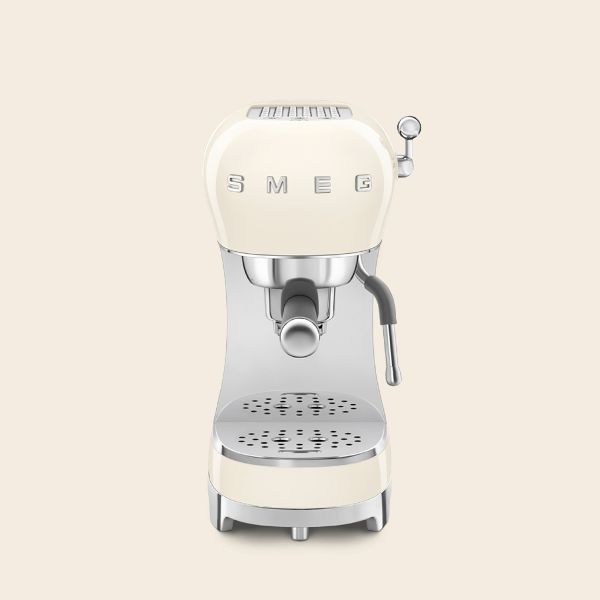

- COFFEE

-

Espresso coffee machines

- Drip filter coffee machines

-

Coffee grinders

- Milk frothers

- separator4

- WATER

- Soda makers

- separator10

- FOOD PREPARATION

-

Stand mixers

- Hand blender

- Blenders

- Hand mixers

- Kitchen scales

- separator11

- KITCHENWARE

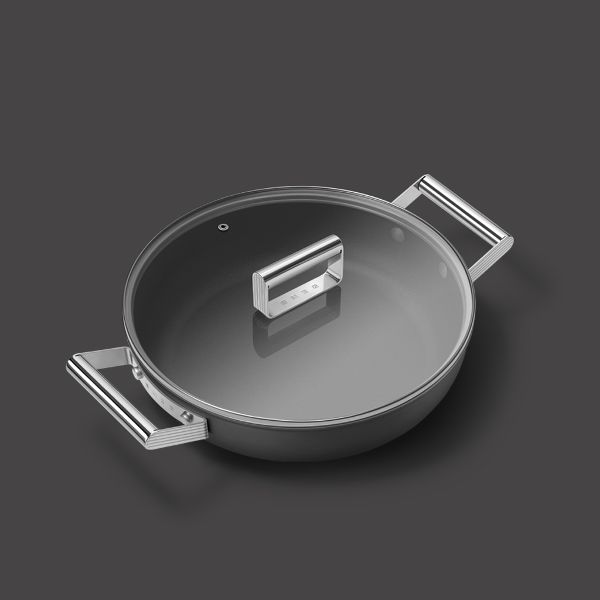

- Cookware

- Knives block set

- separator9

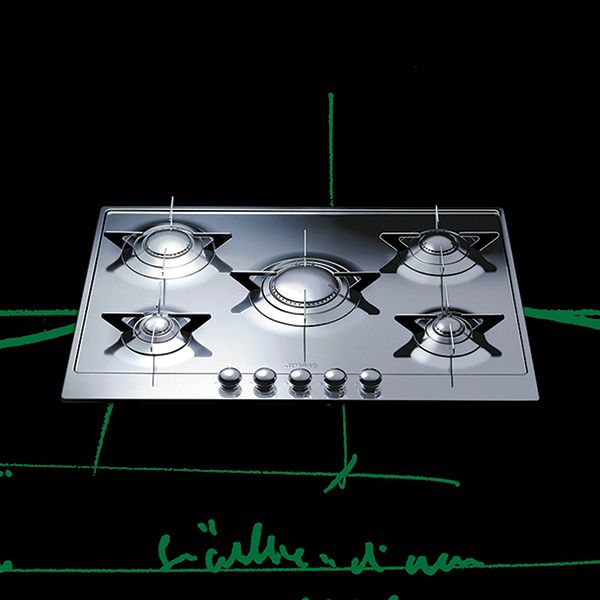

- COOKING

- Countertop combi steam ovens

- Portable induction cookers

- Separator5

- Accessories

- separator

- See all Small appliances

-

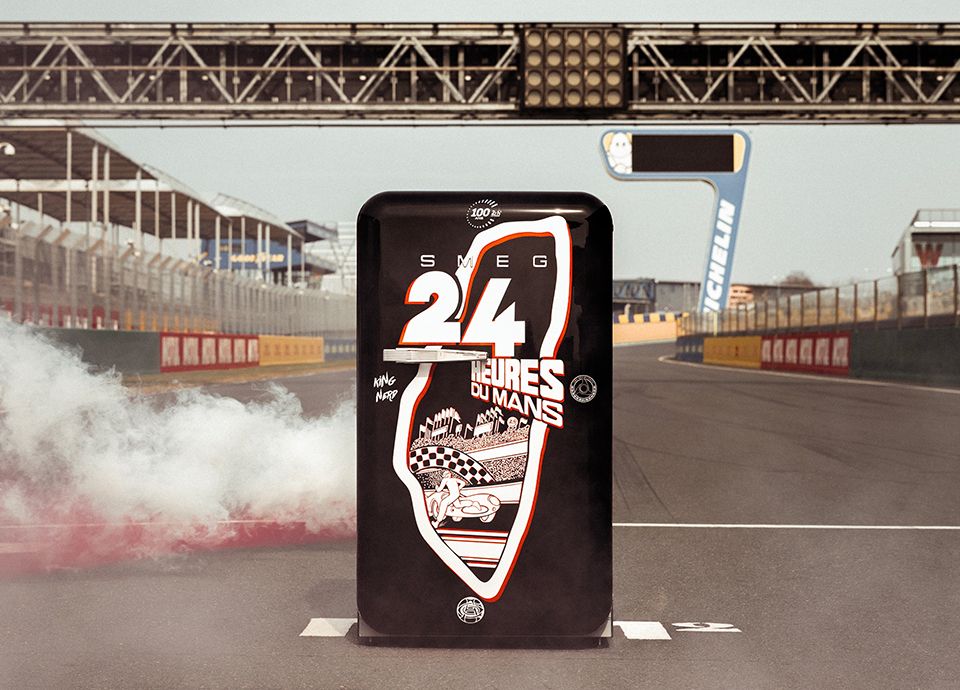

SPECIAL PROJECTS

- AESTHETIC LINES

-

INSPIRATION

Search

Enter at least 3 characters